Application

Nominal sizes

Parts and characteristics

Construction features

Material and surfaces

Standards and guidelines

Maintenance

Useful additions

| Nominal sizes | 100 – 400 mm |

| Volume flow rate range | 12 – 750 l/s or 43 – 2700 m³/h |

| Electrical power consumption | 0.4 – 9 kW |

| Minimum airflow velocity | 1.5 m/s (airflow monitoring required, by others) |

| Maximum outlet airflow temperature | 50 °C (capacity control required, by others) |

| Maximum operating temperature | Without integral control = 40 °C max. |

| Release temperature – temperature monitor TW | Approx. 60 °C (automatic reset if the value falls below this temperature; hysteresis approx. 15 K) |

| Release temperature for thermal cut-out | Approx. 90 °C (manual reset on the air heater required) |

| Air-side static differential pressure | 5 – 75 Pa |

| Supply voltage NS 100 | 230 V AC, 400 W |

| Supply voltage NS 125 | 230 V AC, 900 W |

| Supply voltage NS 160 | 230 V AC, 1200 W |

| Supply voltage NS 200 | 230 V AC, 2100 W |

| Supply voltage NS 250 | 400 V AC 2-phase, 3000 W |

| Supply voltage NS 315 | 400 V AC 3-phase, 6000 W |

| Supply voltage NS 400 | 400 V AC 3-phase, 9000 W |

| Protection level | IP 43 |

| EC conformity | EMC to 2014/30/EU, low voltage to 2014/35/EU |

| Licence | CE, UKCA, S, EAC |

Technical data – electric air heater

Basic units: TVR, RN and VFC

NG | qv | ∆pst [Pa] | te = 16 °C | ||

|---|---|---|---|---|---|

| l/s | m³/h | P [kW] | ta [°C] | ||

| 100 | 12 | 43 | 5 | 0,4 | 44 |

| 100 | 20 | 72 | 10 | 0,4 | 33 |

| 100 | 30 | 108 | 15 | 0,4 | 27 |

| 100 | 40 | 144 | 25 | 0,4 | 24 |

| 100 | 45 | 162 | 30 | 0,4 | 23 |

| 125 | 24 | 85 | 5 | 0,9 | 48 |

| 125 | 35 | 126 | 20 | 0,9 | 37 |

| 125 | 50 | 180 | 40 | 0,9 | 31 |

| 125 | 65 | 234 | 60 | 0,9 | 27 |

| 125 | 75 | 270 | 80 | 0,9 | 26 |

| 160 | 30 | 108 | 5 | 1,2 | 49 |

| 160 | 50 | 180 | 10 | 1,2 | 36 |

| 160 | 70 | 252 | 15 | 1,2 | 30 |

| 160 | 95 | 342 | 25 | 1,2 | 26 |

| 160 | 115 | 414 | 35 | 1,2 | 25 |

| 200 | 59 | 210 | 5 | 2,1 | 46 |

| 200 | 80 | 288 | 20 | 2,1 | 38 |

| 200 | 115 | 414 | 35 | 2,1 | 31 |

| 200 | 150 | 540 | 55 | 2,1 | 28 |

| 200 | 180 | 648 | 80 | 2,1 | 26 |

| 250 | 77 | 275 | 5 | 3 | 49 |

| 250 | 125 | 450 | 15 | 3 | 36 |

| 250 | 180 | 648 | 25 | 3 | 30 |

| 250 | 235 | 846 | 40 | 3 | 27 |

| 250 | 290 | 1044 | 60 | 3 | 25 |

| 315 | 153 | 550 | 5 | 6 | 49 |

| 315 | 200 | 720 | 15 | 6 | 41 |

| 315 | 285 | 1026 | 25 | 6 | 33 |

| 315 | 375 | 1350 | 40 | 6 | 29 |

| 315 | 460 | 1656 | 60 | 6 | 27 |

| 400 | 228 | 820 | 5 | 9 | 49 |

| 400 | 325 | 1170 | 15 | 9 | 39 |

| 400 | 465 | 1674 | 30 | 9 | 32 |

| 400 | 605 | 2178 | 50 | 9 | 28 |

| 400 | 750 | 2700 | 75 | 9 | 26 |

P: Electrical power consumption

te: Inlet airflow temperature

ta: Outlet airflow temperature

qv: Volume flow rate

Δpst: Static differential pressure

Specification text

Electric air heater for reheating airflows in ventilation and air conditioning systems. Dimensions fit VAV terminal units TVR as well as CAV controllers RN and VFC. Integral twofold overheating protection with temperature monitor and thermal cut-out. Spigot with lip seal for ducts according to EN 1506 or EN 13180. Casing leakage according to EN 15727, class C.

Materials and surfaces

Technical data

Sizing data

| EL | / | 160 |

| | | | | |

| 1 | 2 |

| Nominal size | 160 mm |

④ Reset button

Installation and commissioning

Space required for commissioning and maintenance

Sufficient space must be kept clear near any attachments to allow for commissioning and maintenance. It may be necessary to provide sufficiently sized inspection access openings.

④ Reset button

Correct assignment of types for installation, wiring and commissioning; see also the manufacturer's documentation

Order code | Type according to manufacturer (see installation manual) |

|---|---|

EL/100 | CV10 - 04 - 1M |

EL/125 | CV12 - 09 - 1M |

EL/160 | CV16 - 12 - 1M |

EL/200 | CV20 - 21 - 1M |

EL/250 | CV25 - 30 - 2M |

EL/315 | CV31 - 60 - 3M |

EL/400 | CV40 - 90 - 3M |

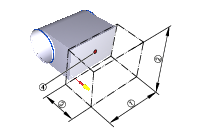

Space required

NS | ① | ② | ③ |

|---|---|---|---|

| 100 | 320 | 125 | 300 |

| 125 | 320 | 150 | 300 |

| 160 | 320 | 185 | 300 |

| 200 | 320 | 225 | 300 |

| 250 | 320 | 275 | 300 |

| 315 | 320 | 340 | 300 |

| 400 | 320 | 425 | 300 |

Share page

Recommend this page

Recommend this page by sending a link by mail.

Share page

Thank you for your recommendation!

Your recommendation has been sent and should arrive shortly.

Contact

We are here for you

Please specify your message and type of request.

Tel.: +44 (0)1842 754545 | Fax: +44 (0)1842 763051

Contact

Thank you for your message!

Your message is send and will be processed shortly.

Our department for Service-Requests will contact you asap.

For general question regarding products or services you can also call:

Tel.: +44 (0)1842 754545 | Fax: +44 (0)1842 763051

Contact

We are here for you

Please specify your message and type of request.

Tel.: +44 (0)1842 754545 | Fax: +44 (0)1842 763051

Contact

Thank you for your message!

Your message is send and will be processed shortly.

Our department for Service-Requests will contact you asap.

For general question regarding products or services you can also call:

Tel.: +44 (0)1842 754545 | Fax: +44 (0)1842 763051