The priorities of today's building owners and occupiers have changed since the pre-COVID period, placing new emphasis on air quality. At the same time, the escalating costs of energy are adding urgency to the ever-present need for best practice environmental performance. These factors have led to a renewal of interest in floor grilles and displacement ventilation. These long-established techniques were often overlooked in the past, but changing priorities have led to a reappraisal of their benefits. Tim Tanner, product technical manager - air diffusers and attenuators at TROX UK has considered the potential advantages of adopting these approaches, and provides advice on the design of systems employing floor grilles and displacement ventilation. This includes tips on the types of project most likely to benefit, and key technical factors such as load testing and air movement strategies. Finally, Tim provides an update on the latest developments in the design of floor grilles/diffusers.

When a mixed air distribution system is installed, the air (this could be for either heating or cooling) is delivered at relatively high velocity from diffusers at ceiling level. As long as the ceiling diffusers have been selected and positioned correctly, this high velocity air will not result in occupant discomfort. This is because it is delivered outside the occupied zone and, as it moves along the ceiling due to coanda effect, it reduces in velocity before entering the occupied zone. This is necessary to prevent problems such as draughts, or 'dumping' of cool air (if the velocity is too low). See Figure 1 below.

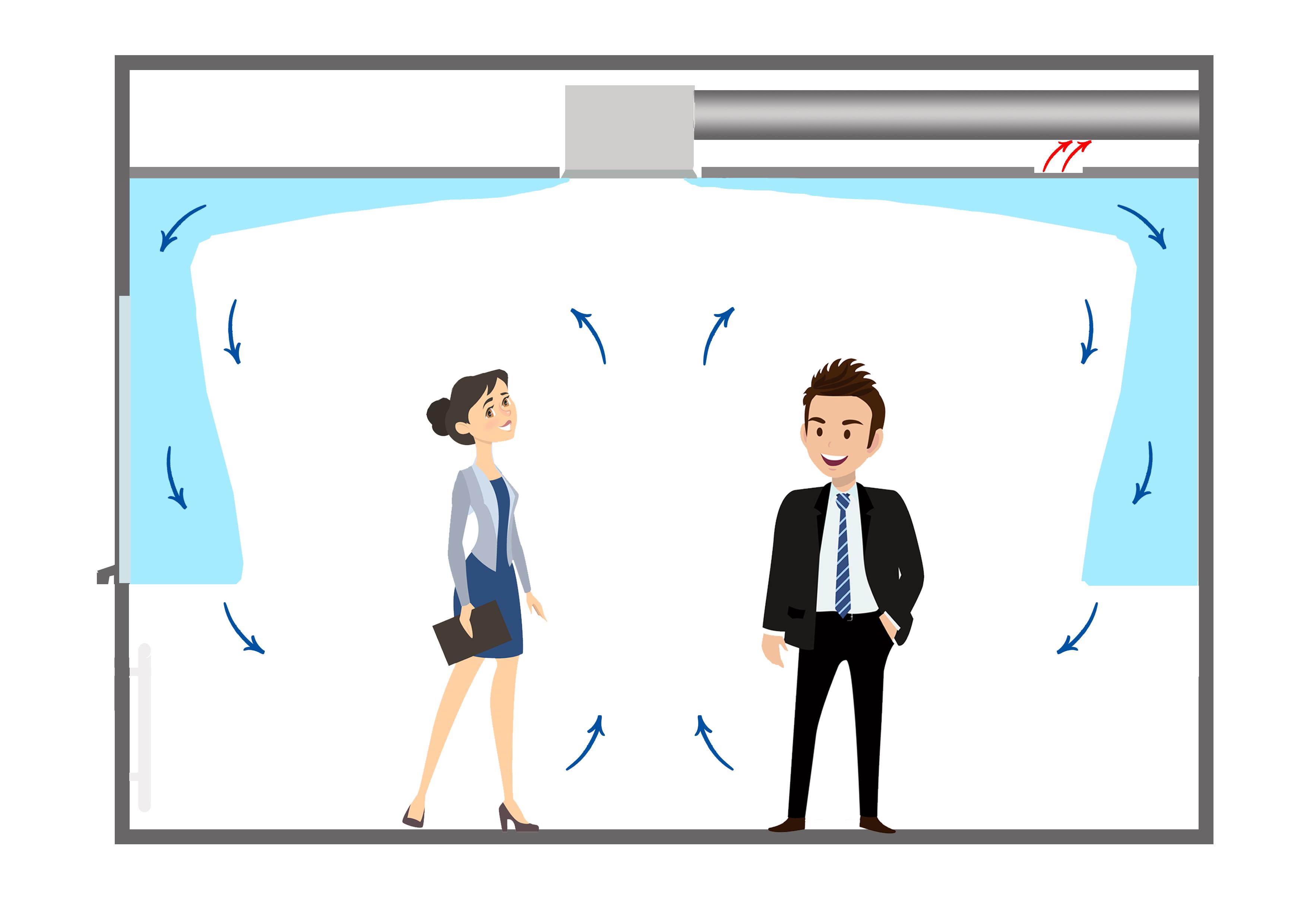

By contrast, underfloor air distribution systems typically employ a displacement air movement strategy. Cool air is delivered at reduced velocity into the room from the floor void, through specially-designed floor grilles. As the supply air is always cooler than the room air, it moves slowly across the room. When the cooler air comes into contact with a heat load, such as a room occupant, it rises towards the ceiling, where the system will include equipment for extraction. See Figure 2 below.

FIGURE 2 - Displacement air ventilation

Secondly, displacement approaches can deliver air quality benefits. As the air pools along the floor, rising when it meets a heat source (such as a person), it can take certain contaminates upwards, out of the occupied zone for ceiling level extract. There are, of course, a number of factors to consider in this regard. For example, floor diffusers and grilles coupled with displacement air strategies may not be suitable for applications where the contaminates will be heavier than air.

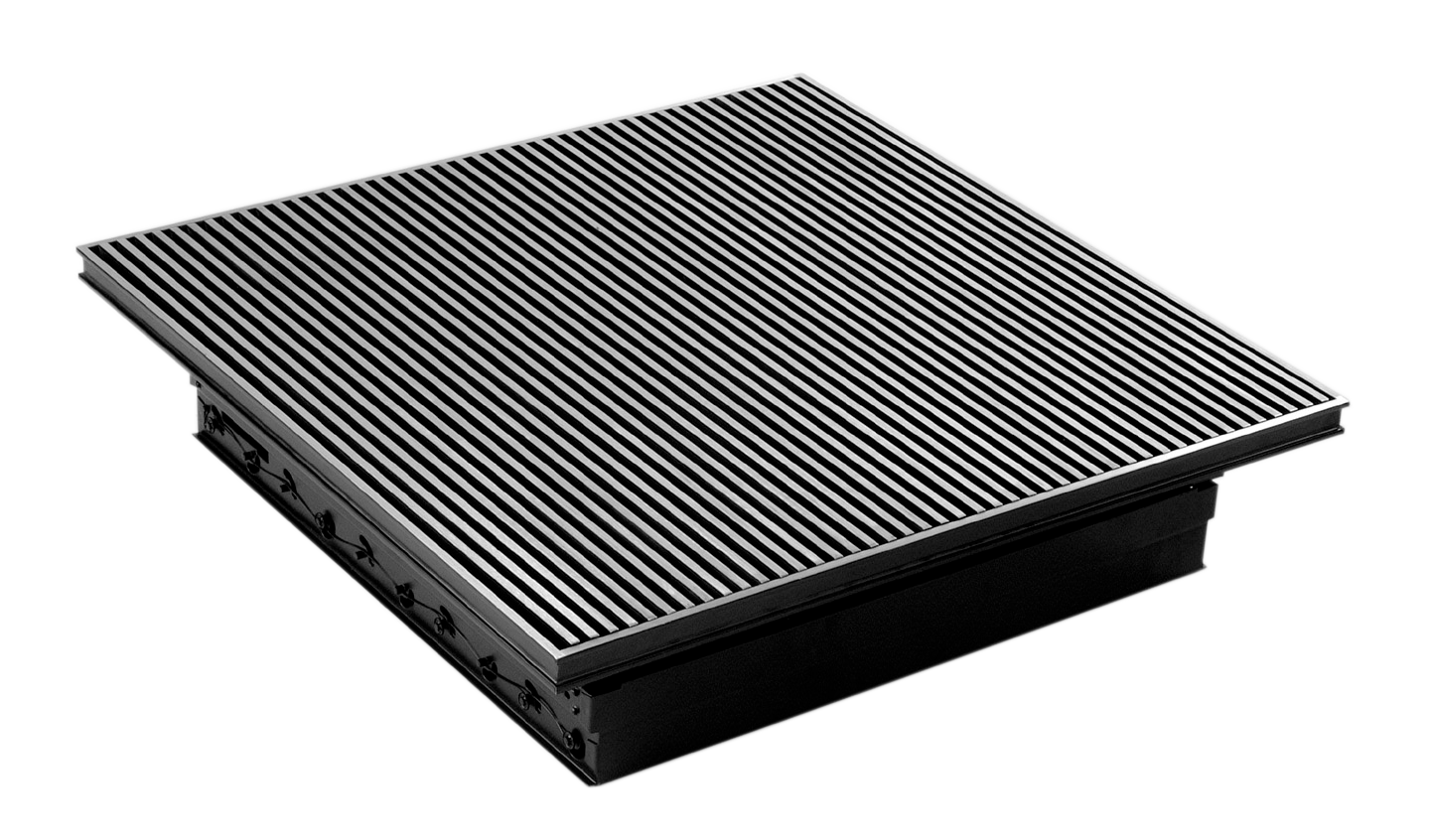

Lastly, there are practical advantages for those installing and maintaining building services, as well as for building owners and occupiers. As the equipment is installed into the floor and floor void, the requirement to work at height is removed, reducing health and safety risk for contractors and service engineers. Furthermore, as floor grilles are typically installed into floor tiles (or designed as replacement 600 x 600 tiles, in the case of the TROX AFG), reconfiguration of spaces is made easier. Since there is little or no ductwork involved, the floor tiles can be easily rearranged, and the tiles incorporating diffusers can simply be moved to different locations to suit each new configuration. Given the frequency and cost of 'churn', this increased flexibility is extremely valuable to building owners and occupiers throughout the lifecycle of the equipment.

The REHVA Guidebook on Displacement Ventilation guidance is as follows:

Displacement ventilation is usually preferable in the following cases:

Displacement ventilation may be less preferable than mixing ventilation in the following cases:

Added to this, applications such as laboratories/science campuses and so on require specialist air management systems. TROX's LabControl systems are purpose-designed for these applications.

IMAGE: TROX AFG floor grille

Having addressed these questions, the key aspects to consider include the following:

Heating requirement – Displacement ventilation requires the supply air to be cooler than the room air. So, this approach is only suitable for cooling with a supply temperature range of -2K to -4K. As a general rule, heating is not recommended using displacement ventilation. The TROX FBA floor diffuser incorporates a swirl unit, this causes high induction and allows for heating, as long as the temperature differential is kept to a minimum. In order to maximize the effectiveness of this heating, the FBAs should be evenly spread throughout the floor plate.

IMAGE: TROX FBA floor diffuser

Acoustic performance – When designing a system using floor grilles/diffusers it is important to consider that these will be within the occupied zone and, most likely, will be much closer to any occupants than a ceiling/wall diffuser would be. Another point to consider is that floor grilles/diffusers will open up a sound path between rooms sharing the same floor void. TROX is happy to assist customers with all aspects of system design, including sound attenuation, and can arrange demonstrations of air movement characteristics at its laboratory in Thetford.

IMAGE: TROX AF linear bar grille

The AF model is typically installed around the perimeter of the occupied space, to discharge cold air up the glazing to mitigate any solar gains. The FBA is designed to be employed for maximum coverage across the rest of the floorplate.

For more information, please contact:

Debbie Giggle, Lighthouse PR

Tel: 01847 831609 Email: Lhousepr@btinternet.com

Neil Bond, Marketing Manager, TROX UK

Tel: 01842 754545 Email: marketing@troxuk.co.uk

About TROX Group

TROX is a global leader in the development, production and sale of components, units and systems for the ventilation and air conditioning of rooms. With 34 subsidiary companies in 29 countries on five continents, 20 production facilities, and importers and representatives, TROX is present in over 70 countries. Currently, the TROX GROUP has around 4,600 employees worldwide and generates revenues of around EUR 600 million.

About TROX UK

TROX UK was established in 1962 in London, UK, as the first international subsidiary of Trox SE, and since 1971 has been based at its manufacturing facility and offices in Caxton Way, Thetford, Norfolk, currently with approx. 150 employees. TROX UK is a manufacturer of air conditioning, ventilation and fire safety products and has the most efficient and flexible range of air distribution systems in the UK market. Working closely with architects, developers and consultants, TROX UK has supplied its products and services to many of the UK's most prestigious buildings and commercial developments.

Share page

Recommend this page

Recommend this page by sending a link by mail.

Share page

Thank you for your recommendation!

Your recommendation has been sent and should arrive shortly.

Contact

We are here for you

Please specify your message and type of request.

Tel.: +44 (0)1842 754545 | Fax: +44 (0)1842 763051

Contact

Thank you for your message!

Your message is send and will be processed shortly.

Our department for Service-Requests will contact you asap.

For general question regarding products or services you can also call:

Tel.: +44 (0)1842 754545 | Fax: +44 (0)1842 763051

Contact

We are here for you

Please specify your message and type of request.

Tel.: +44 (0)1842 754545 | Fax: +44 (0)1842 763051

Contact

Thank you for your message!

Your message is send and will be processed shortly.

Our department for Service-Requests will contact you asap.

For general question regarding products or services you can also call:

Tel.: +44 (0)1842 754545 | Fax: +44 (0)1842 763051